In recent years, stock aluminum extrusions have become more widely used in product development and manufacture. According to Technavio, the demand for aluminum extrusion will increase by around 4% globally between 2019 and 2023. Maybe you’ve heard of this manufacturing process and are interested in learning more about it and how it operates. If so, you have come to the right place.

What Is It?

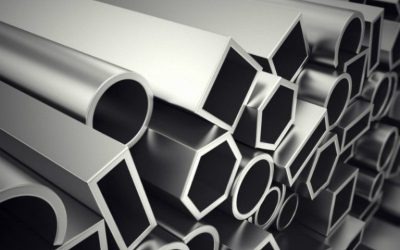

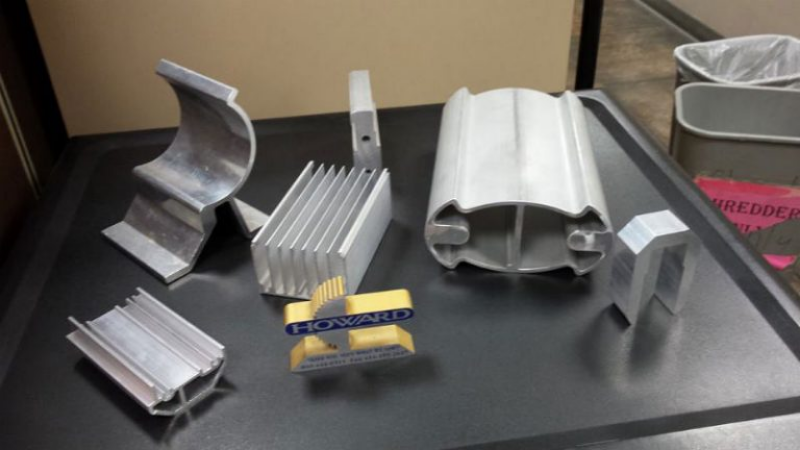

Aluminum alloy material is forced into a die with a specific cross-sectional form using the extrusion method. A powerful ram pushes the metal through the die and out of the aperture to create the extruded aluminum stock. When this occurs, it emerges in the precise shape of the die and is carried away along a runout table.

Fundamentally speaking, the procedure is a straightforward approach. When you squeeze a tube of toothpaste with your hands, the same force is applied. When you press the toothpaste tube, it emerges from the opening. The toothpaste tube’s aperture serves a similar function to an extrusion die.

Types of Processes

Direct and indirect procedures are the two main categories utilized for stock aluminum extrusions. In the direct method, the die head remains immobile during the procedure, which is carried out by a ram that moves back and forth behind the die.

On the other hand, the billet does not move at any point when it comes to the indirect extrusion process. After that, the die assembly will move in opposition to the billet to provide the pressure necessary to push the metal through the die.