In the expansive world of manufacturing, metal stamping companies stand as pivotal players, continually driving innovations that shape how industries operate. These companies utilize sophisticated techniques to transform metal sheets into precise parts used across various sectors, including automotive, aerospace, electronics, and medical devices. As we delve deeper into the contributions of metal stamping in modern manufacturing, it becomes clear how these processes are not just part of the industry but are actively molding its future.

The Role of Metal Stamping in Modern Manufacturing

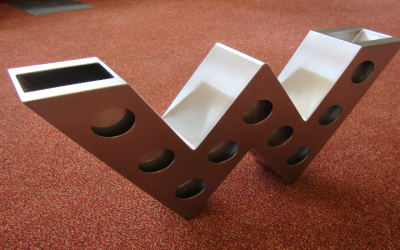

Metal stamping involves several processes such as punching, embossing, bending, and coining. This versatility allows for the production of complex parts that are both durable and cost-effective. Here’s how metal stamping companies are influencing key aspects of the manufacturing sector:

- Innovation in Product Design: Metal stamping supports the design and production of intricate parts. Advanced stamping techniques allow for greater complexity in parts without sacrificing speed or quality, enabling manufacturers to innovate more freely and effectively.

- Efficiency and Scalability: With the aid of high-speed presses and automation, metal stamping companies can produce large volumes of parts quickly, significantly reducing turnaround times and helping manufacturers meet market demands promptly.

- Cost-Effectiveness: Metal stamping is known for its ability to produce high-quality parts while minimizing waste, thereby reducing material costs. The process also allows for the use of various metals, which helps in optimizing costs based on the specific requirements of the project.

- Sustainability: As global emphasis on sustainability intensifies, metal stamping companies are at the forefront of adopting greener practices. This includes using recycled materials and improving processes to reduce energy consumption and waste production.

Technological Advancements Driving Change

The integration of technology into metal stamping has led to groundbreaking changes in manufacturing capabilities. Some of the key technological advancements include:

- Automation and Robotics: Automation in metal stamping not only speeds up the production process but also enhances precision. Robotics has allowed for consistent output quality with minimal human error, making it indispensable in high-stakes manufacturing environments.

- 3D Printing and Prototyping: The adoption of 3D printing for prototyping has revolutionized product development within metal stamping firms. This technology allows for rapid prototyping, reducing the time and cost associated with bringing a new product to market.

- Data Analytics and IoT: The use of data analytics and the Internet of Things (IoT) in metal stamping helps optimize operations and predict maintenance needs. This predictive capability ensures minimal downtime and more efficient production cycles.

Learn more about how these companies are integrating advanced technologies into their processes.

Metal stamping companies are not merely participants in the manufacturing industry; they are its architects, constantly innovating and adapting to meet the demands of a rapidly changing world. From enhancing product design to incorporating sustainable practices and advanced technologies, these companies play a crucial role in setting new standards and driving the future of manufacturing. As technology continues to evolve, the influence of metal stamping on global manufacturing strategies is expected to grow, reaffirming its essential place at the heart of industry innovation.