Metal crafting has become a cornerstone of contemporary manufacturing, offering a blend of precision and versatility that meets a diverse range of industry needs. Various techniques are employed to shape metal components from flat sheets to meet specific requirements. This process is crucial in modern industries, influencing everything from intricate architectural features to industrial machinery. It enhances design flexibility and ensures that components are tailored to meet specific operational demands and performance standards.

Comprehending the Manufacturing Procedure

Sheet metal fabrication involves transforming flat metal sheets into complex parts and structures. The process typically begins with cutting the sheets to the required dimensions. After that, methods like bending, stamping, and pressing are used to shape and form the metal. To guarantee that the finished product fulfills strict quality standards, each stage in this process demands painstaking attention to detail. The capacity of custom sheet metal fabrication to accept bespoke designs is one of its extensive advantages. Manufacturers can customize their offerings to create components that fulfill particular functional and design specifications. This degree of personalization is especially helpful in sectors like aerospace, automobiles, and architecture, where standard components are insufficient. The versatility of tailored metalworking extends to its adaptability for small-scale and large-scale production runs. Whether crafting one-of-a-kind prototypes or high-volume orders, this process ensures precision and consistency, meeting the rigorous demands of specialized industries.

Applications Across Various Industries

The versatility and importance of tailored metalwork are evident across various industries. In the automotive sector, for instance, it is used to create everything from body panels to engine components, delivering precision and durability. Because they are well-built and lightweight, custom-fabricated metal parts are essential to aircraft performance and safety in the aerospace sector. Architectural applications use custom sheet metal fabrication to enhance a building’s visual appeal and use. The ability to produce sophisticated designs and forms suitable for everything from complex facades to structural supports enables innovative and attractive architecture. This adaptability is also present in other industries, such as electronics, where components and enclosures made of bespoke metal are employed. The ability to tailor metal components to specific needs not only improves functionality but also drives innovation in design. From enhancing structural integrity to contributing to aesthetic appeal, customized metalwork plays a pivotal role in advancing technological and architectural achievements across multiple fields.

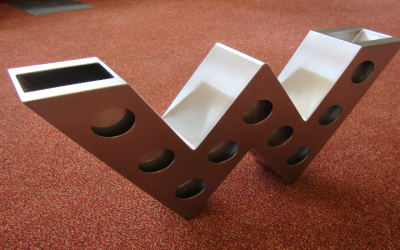

The Role of Custom Sheet Metal Forming

A crucial step in the production process of bespoke sheet metal is forming. This process involves using a variety of techniques, including rolling, hydroforming, and deep drawing, to reshape metal sheets into the appropriate forms. Custom sheet metal forming offers advantages that go beyond simple shape modification. Additionally, it makes the finished product stronger and more durable. Forming is an essential part of high-quality fabrication because manufacturers may produce components that not only meet but also surpass performance requirements by carefully managing the process. In today’s industry, tailored metalworking is a valuable and essential technique. Its ability to produce precise, bespoke components for a variety of sectors highlights its importance. By employing advanced methods and technologies, manufacturers can meet the diverse needs of their clients, resulting in high-quality, custom-made products that endure rigorous demands.