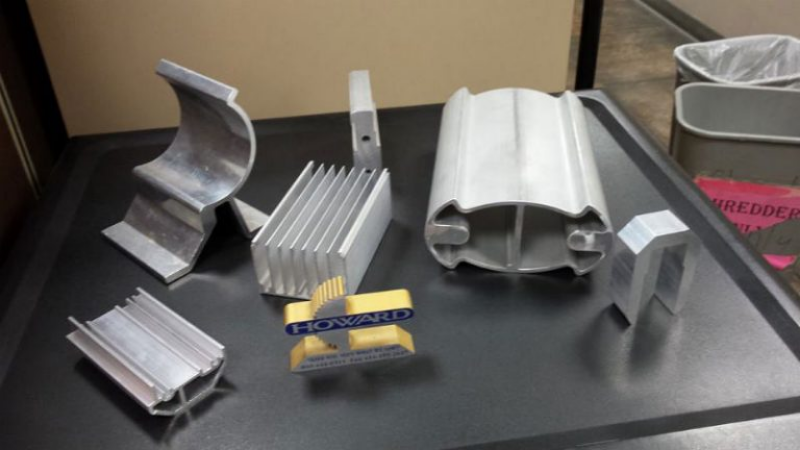

A cast aluminum tooling plate is used for its superior dimensional stability and machinability. Knowing when to use one of these plates may improve the precision and efficiency of your projects.

Here are some of the key scenarios when using cast aluminum tooling plate is beneficial.

High Dimensional Stability

Cast aluminum plates are great for providing dimensional stability. They are manufactured using a casting process that minimizes internal stresses. This stability is needed in applications where precise dimensions are required, such as in jig and fixture making.

Reduction of Internal Stress

Unlike rolled plates, cast aluminum tooling plates undergo a stress-relieving process during manufacturing. This can reduce internal stresses, which can lead to warping and distortion. Using these plates helps support the overall integrity of the final product.

Excellent Flatness and Surface Finish

If flatness and a smooth surface finish are priorities, you may want to use cast aluminum plates. These plates are ground to tight tolerances, ensuring a high degree of flatness. This makes them ideal for use as a base for precision instruments, surface plates, and inspection fixtures.

Lightweight Yet Strong

Despite being lightweight, cast aluminum tooling plates have high strength and rigidity. This combination makes them suitable for applications where weight reduction is important without compromising structural integrity.

These are just a few of the situations where you should consider using cast aluminum plates. They are also great for situations where you need thermal stability or high corrosion resistance. These plates are also well-suited for prototyping and offer excellent machineability.